Metal Powder And Metal Fiber

Production Technology

Metal Powder and Fiber Production Using Modulation Assisted Machining (MAM)®

M4 Sciences is commercializing MAM technology and TriboMAM™ modulation systems to produce a new class of advanced materials. The company has developed a patented low-cost machining process that is capable of producing unique micro-scale metal particles and fibers. M4 Sciences has developed this process, in part, through funding from the National Science Foundation, SBIR IIP Award 0944980 Large-Scale Production of Non-Ferrous Metal Fibers by Modulation-Assisted Machining.

The same chip control that MAM has demonstrated in precision drilling can be adapted in metal machining to generate chips with controlled size and shape. Particles ranging from 0.020mm in size to fibers having length in excess of 20mm with aspect ratios > 100 are possible with MAM. The technology is superior to current technologies, with greater process control and process yield, and direct economic advantages.

MAM enables production of metal particles and fibers in virtually any metal or metal alloy system.

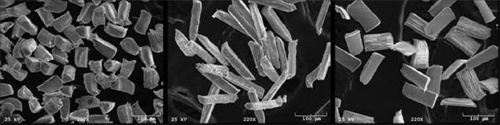

The photomicrograph shows particulate (equal volume particles) formed by MAM in Al6061-T6 aluminum, including equi-axed, fiber (needle), and platelet shapes.

MAM offers a flexible, scalable, and low-cost method for particulate or metal fiber production compared to alternative process routes such as gas phase condensation, cryomilling, or wire bundle drawing processes.

Technical Papers

Metal particulate production by modulation-assisted machining

July 2007